Revolutionizing Automotive Parts Inspection with Automated 3D Scanning

Revolutionizing Automotive Parts Inspection with Automated 3D Scanning

In the fast-paced world of automotive manufacturing, precision and speed are everything. Traditional inspection methods like feeler gauges or contact probes can be slow, inconsistent, and prone to human error. At Rapid Scan 3D, we understand these challenges—which is why we've introduced a powerful automated 3D scanning solution purpose-built for high-volume parts inspection.

The Challenge with Traditional Inspection Methods

Automotive manufacturers have long relied on manual tools to verify gap and flushness across car panels and assemblies. But these methods often result in:

-

Inconsistent Measurements: Manual tools lack the repeatability required for high-volume production environments.

-

Increased Labor Costs: Skilled inspectors are needed for hands-on evaluation, often slowing down production.

-

Quality Risks: Small measurement errors can lead to assembly issues, rework, or customer dissatisfaction.

Our Turnkey Automated 3D Scanning Solution

Our Turnkey Automated 3D Scanning Solution

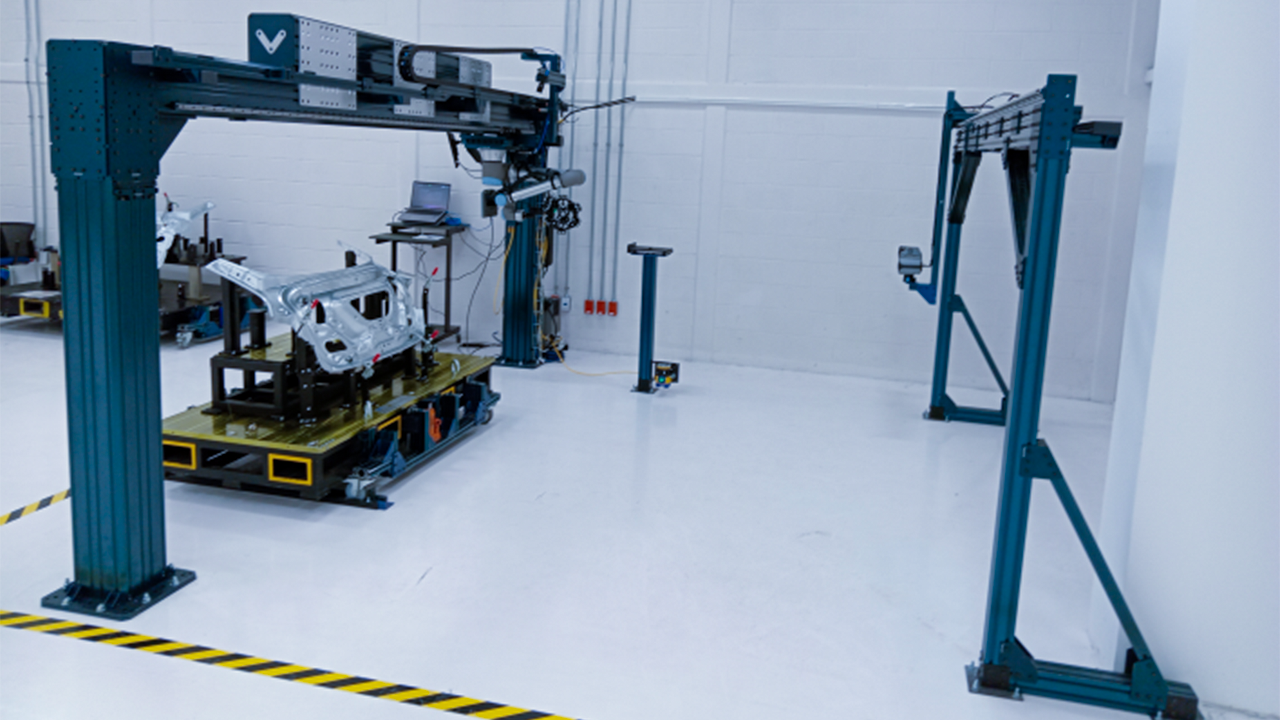

Rapid Scan 3D’s automated solution brings together best-in-class 3D scanning hardware, robotics integration, and intelligent inspection software to provide accurate, repeatable results with zero disruption to production lines.

1. High-Precision 3D Scanners

Utilizing advanced structured-light or laser 3D scanners, we capture high-resolution point clouds of each part. These industrial-grade scanners are built for rugged environments and deliver sub-millimeter accuracy—ideal for inspecting small gaps and complex geometries.

2. Flexible Robotic Movement

Mounted on rails or gantries, the scanner moves autonomously around the part, capturing critical inspection zones without stopping or slowing down the line. This hands-free system supports both inline and near-line deployment.

3. Automated Metrology Software

Our software intelligently processes the scan data in real-time, automatically aligning each part to its CAD reference and measuring key dimensions. Results—including gap and flush values—are generated within 60 seconds and can be logged or flagged based on tolerances.

Proven Accuracy and Repeatability

In validation tests, our system delivered:

| Metric | Performance |

|---|---|

| Measurement Repeatability | Within ±0.2 mm |

| Inspection Time | Less than 60 seconds/unit |

| Production Impact | No line downtime |

This level of speed and precision ensures compliance with strict automotive quality standards while reducing the risk of downstream assembly issues.

Key Benefits for Automotive Manufacturers

-

Contactless, Repeatable Measurements

-

Faster Cycle Times

-

Reduced Labor Costs

-

Digital Traceability for Every Part

-

Easily Configurable for New Models or Lines

Ready to Upgrade Your Inspection Workflow?

Rapid Scan 3D helps manufacturers modernize their quality control process with fully integrated 3D scanning systems. Whether you’re producing vehicle bodies, structural components, or high-tolerance assemblies, our automated solution ensures your inspection process is faster, more accurate, and built for the future.

Interested in learning more or scheduling a demo?

Contact the Rapid Scan 3D team today to explore how we can bring automation and precision to your manufacturing environment.

Original Article

https://www.linkedin.com/pulse/automated-3d-scanning-soltuion-automotive-parts-inspection-hpd5c/