Can 3D Scanning Help with Quality Control Inspection?

In manufacturing, precision isn’t just important — it’s critical. Aerospace, automotive, medical, and industrial companies all rely on parts that meet strict tolerances. That’s why 3D scanning for quality control has become a powerful tool for modern inspection workflows.

What is 3D Scanning for Quality Control?

3D scanning uses advanced laser or structured-light scanners to capture the exact dimensions of a part or assembly. The resulting digital 3D model can then be compared directly against CAD data or engineering specifications.

This process allows companies to:

-

Identify dimensional deviations instantly

-

Perform full-part inspections instead of sampling

-

Measure complex geometries beyond the reach of traditional tools

-

Maintain a digital record of every inspected part

Why Use 3D Scanning Over Traditional Methods?

While calipers, micrometers, and CMMs remain valuable, they have limitations when it comes to speed and complexity.

3D scanning inspection services provide:

-

Speed – Millions of data points in seconds for faster reporting

-

Accuracy – Micron-level precision for tight tolerances

-

Flexibility – Suitable for small components, large assemblies, and freeform surfaces

-

Automation – Integrated with inspection software for consistent results

Applications of 3D Scanning in Inspection

Companies across industries are leveraging 3D scanning inspection services for:

-

First Article Inspection (FAI) – validating initial production runs

-

In-Process Quality Control – catching defects before scaling production

-

Dimensional Inspection – ensuring compliance with design tolerances

-

Reverse Engineering – verifying or recreating parts without CAD files

-

Maintenance & Wear Analysis – checking tooling, molds, or high-use parts

How Rapid Scan 3D Supports Quality Control

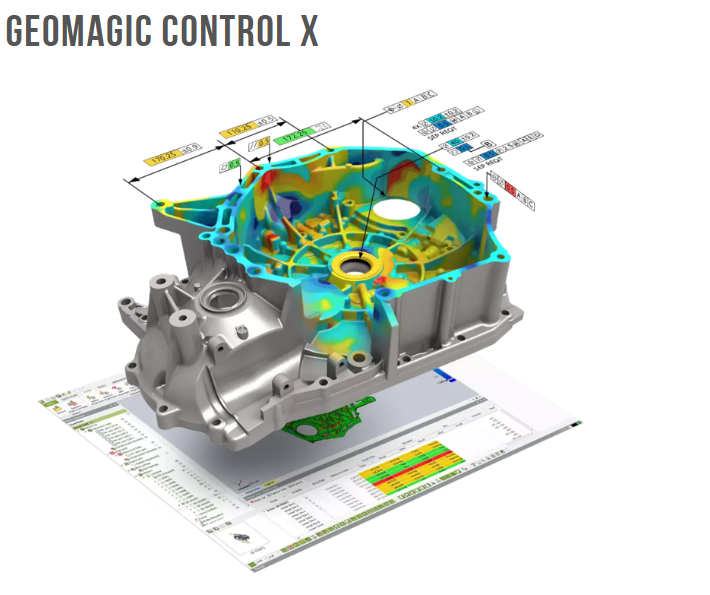

At Rapid Scan 3D, we provide advanced 3D scanning inspection solutions to help manufacturers reduce errors and streamline workflows. Using industry-leading hardware and software like Geomagic Control X and Polyworks Inspector, our team delivers:

-

Accurate dimensional inspection reports

-

Automated workflows for repeatable QA checks

-

Scalable solutions for manufacturing, aerospace, automotive, and beyond

Whether you need one-time inspection services or a fully integrated solution, Rapid Scan 3D is your trusted partner for quality control with 3D scanning.

Final Thoughts

So, can 3D scanning help with quality control inspection? The answer is absolutely yes. By offering greater accuracy, speed, and flexibility, 3D scanning is transforming how manufacturers approach inspection.

👉 Contact Rapid Scan 3D today to schedule a demo or learn how our 3D scanning inspection services can elevate your quality control process.